- Joined

- Feb 15, 2012

- Messages

- 9,608

- Reaction score

- 4,449

Well, decided to pull the trigger on this. Took about a day's work to install. The AirWolf folks were very helpful and available on the phone, we needed to clarify a few things. Package came complete with all the hardware, detailed instructions, and the STC and 8130. We just needed some more length of hose.

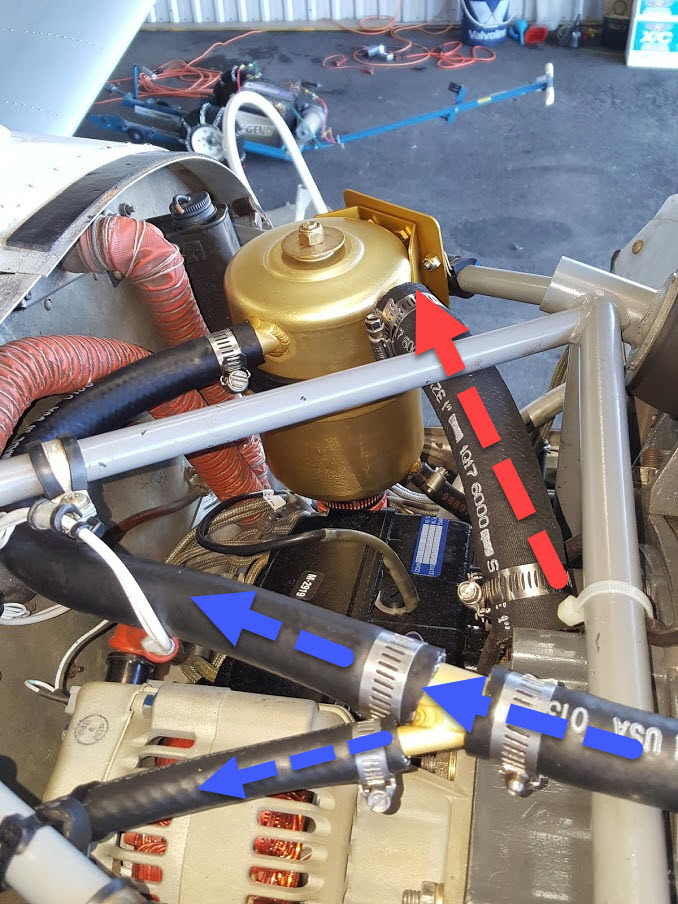

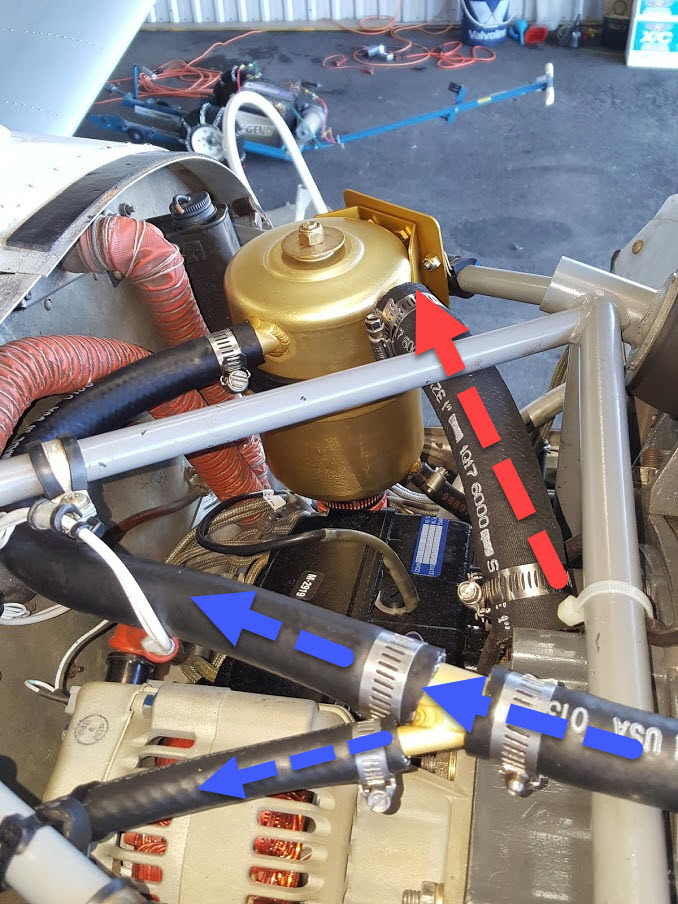

Engine view from the top, the red arrow is the engine breather exhaust. The blue arrow shows hot impact air stolen from the high pressure area above the engine. My plane is all electric, so no vacuum exhaust to scavenge. This drives the exchange chamber, spinning the engine breather exhaust mixture to separate the oil from air/steam.

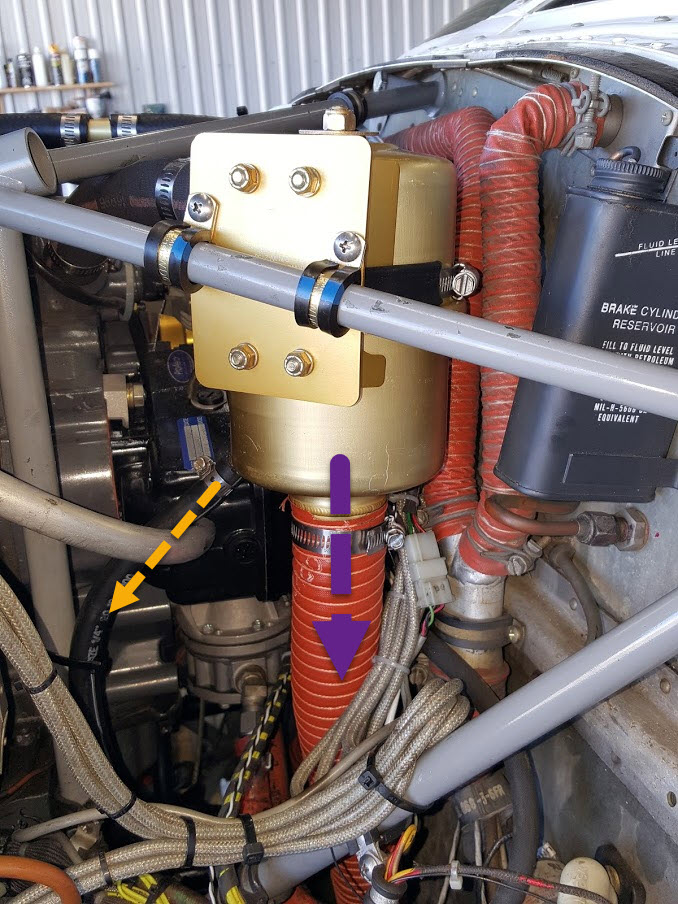

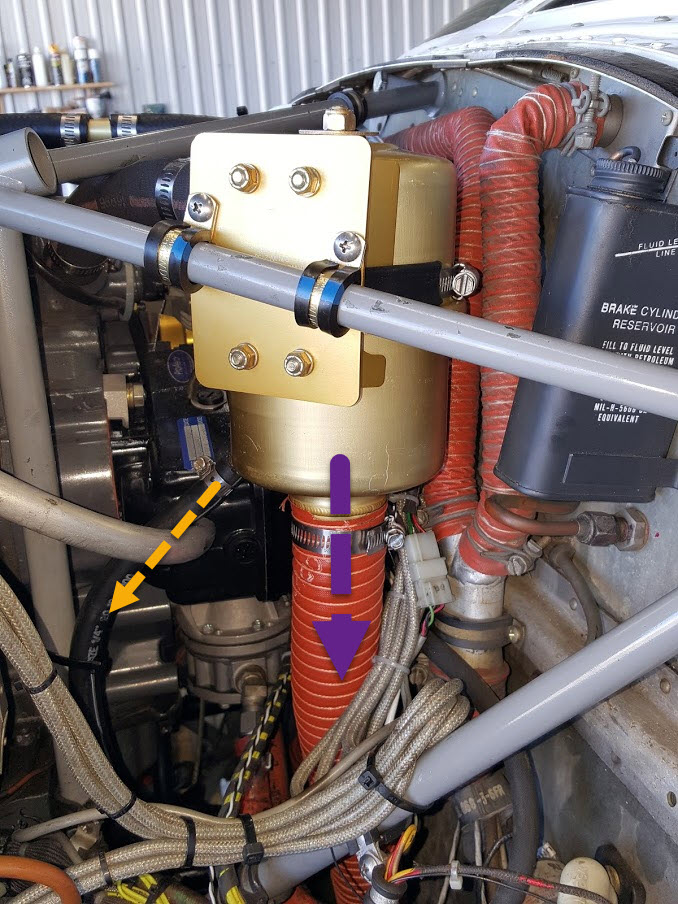

From the pilot's side. Magenta arrow is the new engine breather exhaust, now it expels hot air & steam only, and minimal oil. The Orange arrow is the return oil to the engine.

The oil return (orange) is ducted to a spare sump plug, available on my engine close to the vernatherm. There is some impact air (blue arrow) used to help keep the oil return line drained with a venturi effect. Can also be dumped to a T on an oil return line, or even to a modified rocker cover.

Why did I do this? I have seen high oil "usage" (5 to 7 hrs/qt), and lots of oil on the belly streaming from the breather location. The oil remains clean and the sump is not pressurized (checked with an ASI) and compressions are solid on this low hour engine, exhaust is also clean with the faint white powder (lead salts) of LOP ops, and the case is dry with no oil "on the floor" -- except under the breather!

Having isolated the issue to the breather, tried playing with the whistle holes, ensured the opening was well out of the stream. Didn't help. And yes, I run with only 9qts full in this 6 cylinder.

I could have accepted the higher oil usage, and just dumped an extra quart in now and then. That would have been the cost efficient route, so I didn't bother.

But, that could also hide a real oil loss problem, that is, one that is actually significant and a concern. So we put the Air Wolf in.

Downsides? Well the oft proffered issue of recycling dirty acidic oil seems weak. If it was not being pushed out of the breather in the first place, it wouldn't need to be recycled.

The other concern of dumping water back in is a potential issue, but the inside temps of the separator are well above the boiling point. Steam should be dumped out for the most part, just like it is out the factory breather.

The other issue is that the impact air used to drive the system is unfiltered, and is being dumped, at least in part, into the sump. Discussed this with the AirWolf folks, they haven't seen it reported as a problem. They also had big concerns about adding a filter to their stock inlet, as it would affect the ram air stream that drives the system. Will watch the oil reports for an increase in silica.

* Orest

Engine view from the top, the red arrow is the engine breather exhaust. The blue arrow shows hot impact air stolen from the high pressure area above the engine. My plane is all electric, so no vacuum exhaust to scavenge. This drives the exchange chamber, spinning the engine breather exhaust mixture to separate the oil from air/steam.

From the pilot's side. Magenta arrow is the new engine breather exhaust, now it expels hot air & steam only, and minimal oil. The Orange arrow is the return oil to the engine.

The oil return (orange) is ducted to a spare sump plug, available on my engine close to the vernatherm. There is some impact air (blue arrow) used to help keep the oil return line drained with a venturi effect. Can also be dumped to a T on an oil return line, or even to a modified rocker cover.

Why did I do this? I have seen high oil "usage" (5 to 7 hrs/qt), and lots of oil on the belly streaming from the breather location. The oil remains clean and the sump is not pressurized (checked with an ASI) and compressions are solid on this low hour engine, exhaust is also clean with the faint white powder (lead salts) of LOP ops, and the case is dry with no oil "on the floor" -- except under the breather!

Having isolated the issue to the breather, tried playing with the whistle holes, ensured the opening was well out of the stream. Didn't help. And yes, I run with only 9qts full in this 6 cylinder.

I could have accepted the higher oil usage, and just dumped an extra quart in now and then. That would have been the cost efficient route, so I didn't bother.

But, that could also hide a real oil loss problem, that is, one that is actually significant and a concern. So we put the Air Wolf in.

Downsides? Well the oft proffered issue of recycling dirty acidic oil seems weak. If it was not being pushed out of the breather in the first place, it wouldn't need to be recycled.

The other concern of dumping water back in is a potential issue, but the inside temps of the separator are well above the boiling point. Steam should be dumped out for the most part, just like it is out the factory breather.

The other issue is that the impact air used to drive the system is unfiltered, and is being dumped, at least in part, into the sump. Discussed this with the AirWolf folks, they haven't seen it reported as a problem. They also had big concerns about adding a filter to their stock inlet, as it would affect the ram air stream that drives the system. Will watch the oil reports for an increase in silica.

* Orest